Introduction to Seikei Engineering

At Seikei Engineering, we handle a wide range of projects, focusing on equipment design, plant engineering, installation and construction work, and musical fountain systems.

Guided by our philosophy, “Peach and plum trees say nothing, yet paths form naturally beneath them,” we provide diverse technical solutions spanning equipment design, plant design, installation work, and the design and operation of musical fountains.

With recycling systems that achieve recovery rates of over 80% and engineering solutions developed in close partnership with our clients, we have succeeded in reducing wastewater and cutting costs, earning their trust.

With sincerity and technical expertise, we will continue to walk alongside you in creating new paths together.

Our Products at Work in Various Fields

Achieving Significant Cost Reduction with High Recovery Rates

In semiconductor ingot cutting processes, the recycling rate of used slurry (a mixture of solids and liquids) and semiconductor cutting wastewater has historically been very low, posing a significant challenge for the industry. However, through continuous discussions with clients and repeated improvements, Seikei Engineering succeeded in developing a high-recovery abrasive and grinding material recycling system that competitors were unable to achieve.

By achieving recovery rates of over 80%, we have also made it possible to reduce costs by more than 70%, earning strong praise and satisfaction from our clients.

Automation Through Customized Equipment

We propose equipment sizing and overall layout planning based on the available installation space in each factory. By eliminating dead space and optimizing workflow, we also help improve the working environment.

In addition, we provide solutions for fully automated operations and for reducing hazardous or inefficient processes, thereby streamlining specialized daily tasks and improving overall efficiency.

Fields of Application

Industries where our equipment has been introduced

Semiconductor Manufacturing

Processing Companies

- Wafer cutting wastewater

- Grinding / polishing slurry wastewater

Materials and Chemical Manufacturers

- Ion-exchange resin regeneration wastewater

- Nitric acid / fluoride wastewater

- CMP wastewater

- Etching and cleaning wastewater

- TMAH wastewater

- Lapping process wastewater

Automobile Manufacturing Parts Processing Companies

- Ion-exchange resin regeneration wastewater

- Nitric acid / fluoride wastewater

- CMP wastewater

- Etching and cleaning wastewater

- TMAH wastewater

- Lapping process wastewater

Environmental Equipment Companies

- Various scrubber wastewaters

- Advanced sewage treatment wastewater

- Final disposal site leachate

- High-concentration acid waste

- Alkaline wastewater

Musical Fountains

Seikei Engineering’s expertise in equipment and program design is also applied to musical fountain systems.

We create captivating displays by programming water movements and lighting effects in harmony with the music of your choice, helping to bring an enchanting and immersive experience to life.

Product Lineup

Here is an introduction to our product lineup, which is actively used at worksites across Japan.

Abrasive and Grinding Material Recycling System

By recovering and reusing the abrasive grains and liquid contained in slurry from semiconductor wafer cutting, this system makes it possible to significantly reduce both running costs and the volume of waste generated.

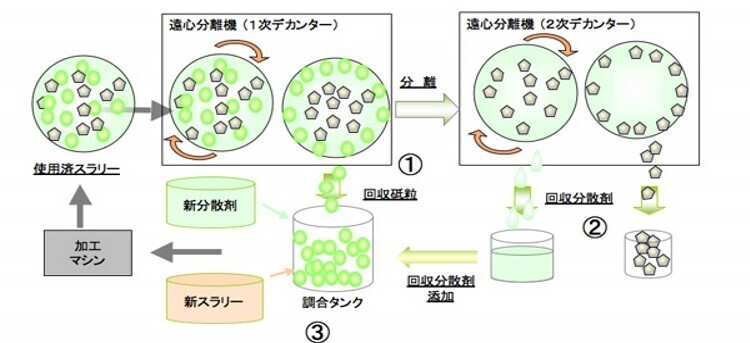

Overview of the Slurry Recycling System

①Used slurry discharged from processing machines is separated by a centrifugal separator to recover the abrasive grains.

②The slurry undergoes an additional centrifugal separation to recover the dispersant, while chips and debris are discarded.

③The recovered abrasive grains and dispersant are then remixed, and fresh slurry components (new abrasive grains and dispersant) are added to produce regenerated slurry for reuse.

◆ Achieving High Recycling Efficiency

Recovery rates of abrasives and solvents (such as coolants) exceed 80%

(subject to variation depending on slurry properties)

◆ Fully Automated, Operator-Free Operation

Continuous automatic control enables stable performance without manual intervention.

◆ Customizable Unit-Based Design

Layouts can be tailored to match available installation space, with proposals provided for optimal integration.

【Recycling Examples】

Slurry from semiconductor silicon processing

Slurry from semiconductor special materials (rare metals)

Slurry from solar cell silicon processing

Slurry from glass polishing

Reference: Abrasive Recovery System – Product Information, Machinery Division | Tomoe Engineering Co., Ltd. (tomo-e.co.jp)

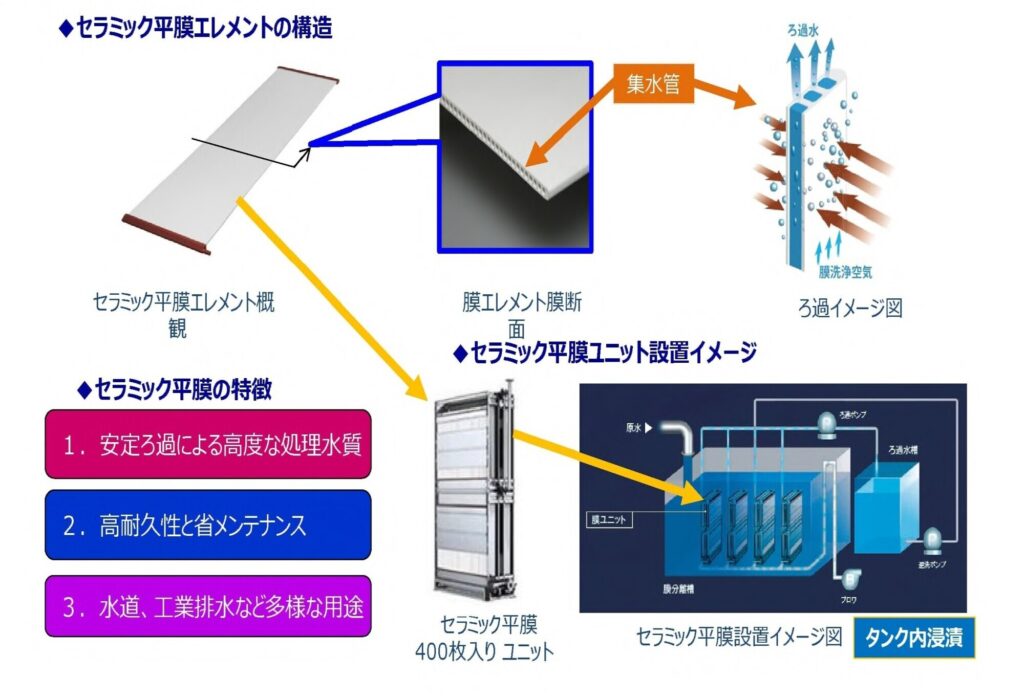

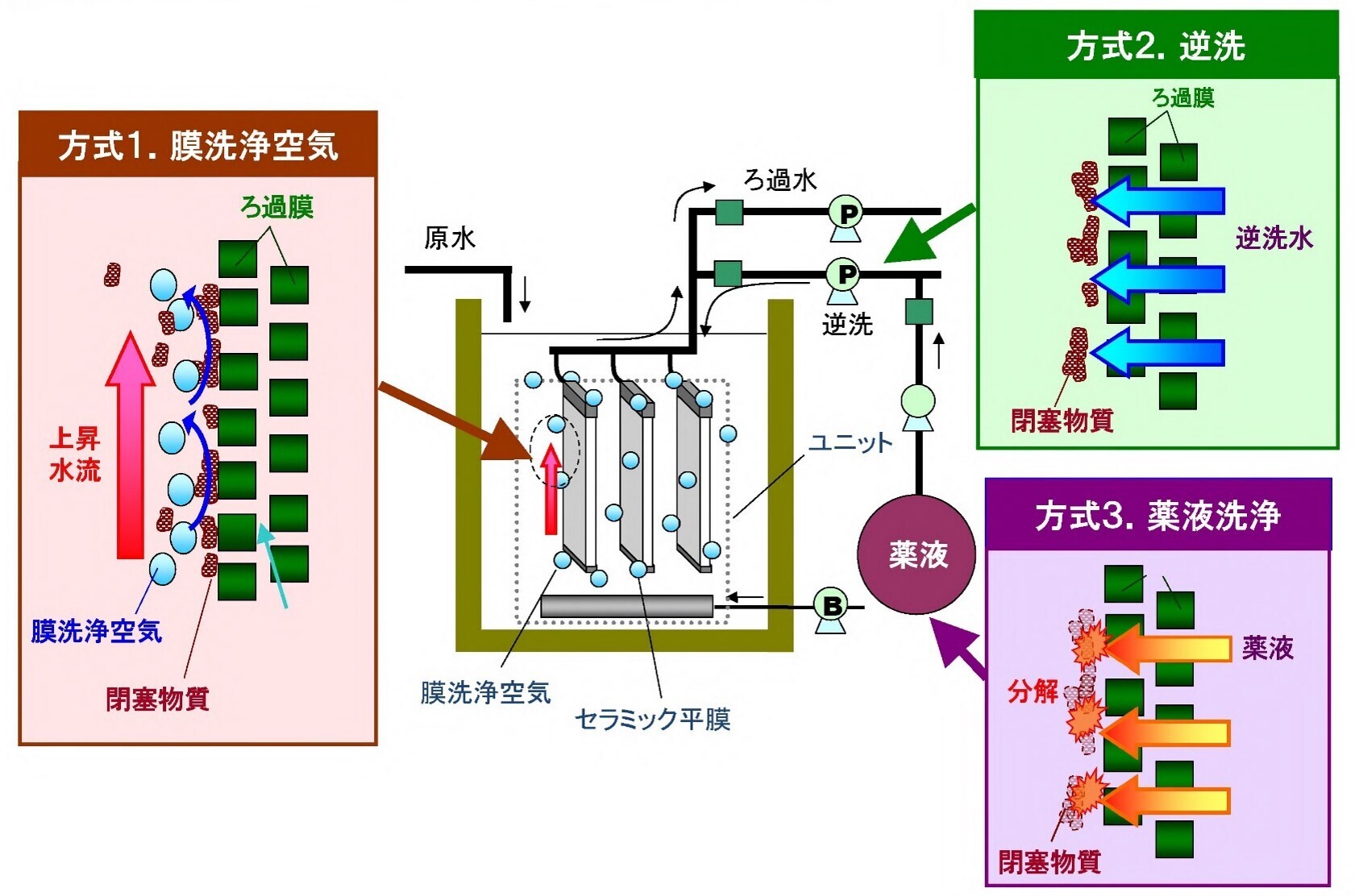

Ceramic Flat Membrane Filtration System

◆ Recovery and Reuse of Valuable Materials

Valuable substances in liquids (such as rare metals) are recovered as concentrated solutions. Liquids used in grinding can also be reused, reducing resource consumption.

◆ Operation Management According to Recovered Materials

The system monitors the pressure applied to the membrane to ensure stable filtration. Filtration and backwashing times can be adjusted depending on the type of material being recovered.

◆ Customizable Unit-Based Design

Unit-based design allows flexible layouts tailored to installation space, with layout planning and proposals provided to optimize factory integration.

【Recycling Examples】

Semiconductor grinding wastewater

Polishing wastewater

Reference: Ceramic Flat Membrane System | Water Treatment Products | Meidensha Co., Ltd. (meidensha.co.jp)

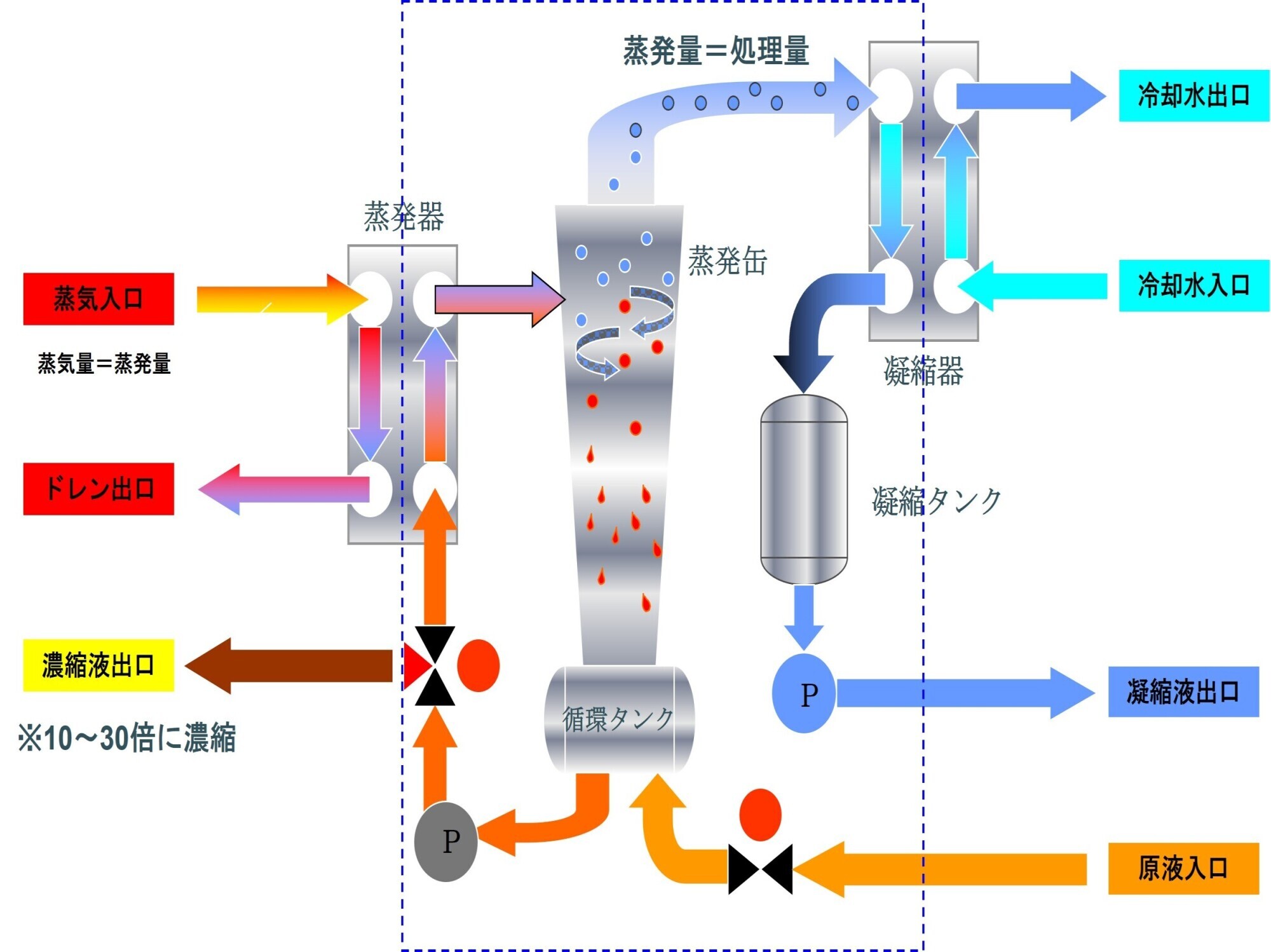

Vacuum Evaporation Concentration System

◆ Recovery and Reuse of Valuable Materials

Evaporated solvents can be cooled, recovered, and reused, improving resource efficiency.

◆ Wastewater Volume Reduction

Significantly reduces the amount of liquid waste, leading to major cost savings in industrial waste disposal.

◆ Use of Steam as a Heat Source

Utilizes low-pressure steam (waste steam) for vacuum concentration, making energy use more efficient.

◆ Fully Automated, Operator-Free Operation

Concentration ratios are automatically controlled and monitored to prevent over- or under-concentration. With intuitive touch-panel operation, no specialized daily tasks are required.

◆ Customizable Unit-Based Design

The unit-based design allows flexible layouts tailored to available installation space, with proposals provided for optimal integration.

Musical Fountain Projects

◆ Construction of Musical Fountain Systems

We provide comprehensive proposals for entire fountain systems, including lighting and speaker setups to enhance the performance.

◆ Programming of Water Movements and Lighting

Water displays and lighting effects are programmed in synchronization with music. The fountain can be designed to express the image of the music or reflect specific requests from clients.

◆ Settings According to Operating Hours and Weather

The system can be configured to operate at desired times and to adapt to weather conditions, ensuring flexible and reliable performance.

【Implementation Example】

Musical Fountain at Hekinan Seaside Park

Frequently Asked Questions

Is it possible to place an order starting from a small lot?

Absolutely. We accept orders starting from just a single unit. Please feel free to contact us.

Can I request only a quotation for now?

Of course. We would be happy to discuss your current situation as part of the process. Please feel free to reach out to us.

Can you provide improvement proposals for existing equipment?

Yes, we can. We will review current issues and suggest improvements to help create a better working environment.

Company Profile

| Company Name | Seikei Engineering Co., Ltd. |

| Address | 〒464-0851 1F Sawada Building, 17-4 Imaike Minami, Chikusa-ku, Nagoya-shi, Aichi |

| TEL | 052-753-6272 |

| Representative | Naoki Machida |

| Capital | 3,000,000 yen |

| Established | October 2021 |

About Tea Sales

We also offer online sales of our carefully selected teas. Fragrant and full of flavor, our premium tea leaves are available for both everyday enjoyment and as special gifts. Please feel free to take advantage of our service.

〒464-0851 1F Sawada Building, 17-4 Imaike Minami, Chikusa-ku, Nagoya-shi, Aichi, Japan

Copyright © Seikei Engineering Co.,ltd. All Rights Reserved.